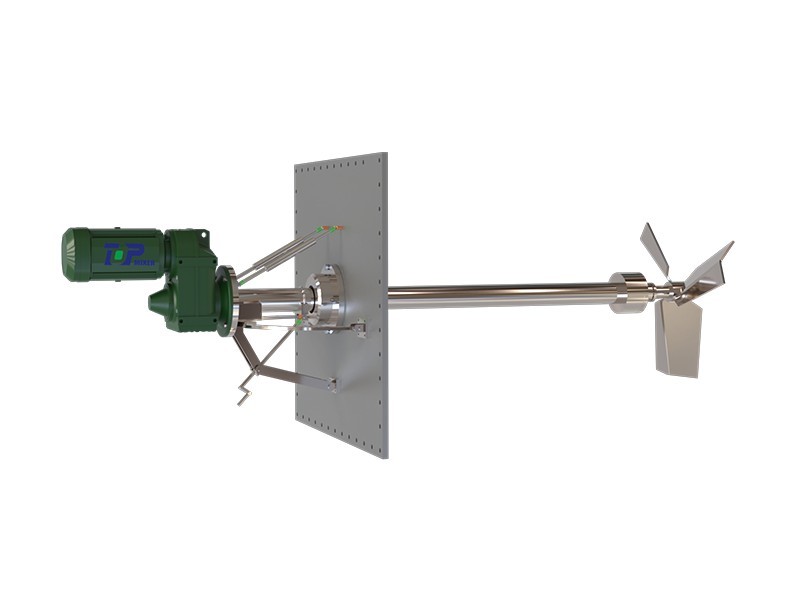

TOP3007 Adjustable Side-Entry Mixer

The TOP3007 adjustable angle side-entry impeller is suitable for the reaction, mixing, and storage of liquid-liquid, solid-liquid, and other materials in various industries. Suitable for biogas, petrochemical, environmental protection, and other industries, especially for large tanks (sumps). The oscillating shaft structure is mainly used for situations where the impeller needs to be adjusted intermittently, especially for large tanks and impeller cracking. With the same power consumption, a larger mixing range can be achieved to avoid dead corners. When installed in the middle and lower part of the tank, its main function is suspension, dispersion, and circulation formation. When installed at the top of the tank, its main function is to enhance circulation and avoid the formation of a stagnant water layer. This series of impellers can be equipped with an impeller anti-fouling device and a leakage indicator.

TOP3007 Adjustable Side-Entry Mixer

The TOP3007 adjustable angle side-entry impeller is suitable for the reaction, mixing, and storage of liquid-liquid, solid-liquid, and other materials in various industries. Suitable for biogas, petrochemical, environmental protection, and other industries, especially for large storage tanks (sumps). The oscillating shaft structure is mainly used for situations where the stirrer needs to be adjusted intermittently, especially for large tanks and stirrer cracking. With the same power consumption, a larger mixing range can be achieved to avoid dead corners. When installed in the lower middle part of the tank, its main function is suspension, dispersion, and circulation formation. When installed at the top of the tank, its main function is to enhance circulation and avoid floating water layers. This series of impellers can be equipped with an impeller anti-hanging device and a leak indicator.

● Compact and high-strength gear structure with a longer service life.

● Robust bearings with a service life exceeding 100,000 hours.

● Single shaft design ensures precision and provides stability.

● Four-directional angle adjustment provides more efficient mixing performance.

● Specially designed seals are suitable for almost all situations.

● Electric or manual rotation device available.

● Specially designed clean-edge impellers prevent fiber entanglement.

Remarks:

● The weight in the table is approximate and does not include the weight of the suspension and anchor bolts.

● The flange dimensions in the table can be replaced with European and American standards.

● The installation method shown is the size of the mounting port on the side of the mixing container that can be selected when side mounting.

● The weight of the motor in the table is the approximate weight of a common indoor motor, which may vary due to different manufacturers and motor types. Please refer to the actual design.

● When the mixing container wall is too thin and the strength is insufficient, please use reinforcing ribs and other auxiliary reinforcement measures.

| Application Rod stirrer Dry matter content up to 14% Substrate temperature up to 70°C pH value 6.5 - 8.2 | Bearings 2 conical roller bearings to absorb axial forces Mechanical seal Silicon carbide/Silicon carbide, any direction of rotation Center bearing of the drive shaft (sliding bearing) |

| Technical Data Stirrer rod length 3.0 / 4.0 meters Rod Ø 101.6 x 4.0 (max. 3 meters) or x 5.7 mm stainless steel 304 or 316 Sealing plate 98x98/120x120/143x143 cm stainless steel 304 or 316 Sound pressure level 75 dB(A) Sealing membrane EPDM60 Installation height in liquid level to 8 meters, deeper please consult Standard is support rod Oil cup for checking the tightness of the stirrer Optional: PTO with tractor protection (max. blade HD+ 700) The stirrer is completely modular in design POM protection to reduce friction | Blades 3-piece high-efficiency dynamically balanced blades FR1: 7.5 kW 200 rpm Blade HD+ 850 FR3: 11.0 kW 275 rpm Blade HD+ 800 FR3: 11.0 kW 400 rpm Blade HD+ 620 FR4: 15.0 kW 275 rpm Blade HD+ 850 FR4: 15.0 kW 400 rpm Blade HD+ 660 FR5: 18.5 kW 275 rpm Blade HD+ 880 FR5: 18.5 kW 400 rpm Blade HD+ 700 FR5: 22.0 kW 400 rpm Blade HD+ 750 Material Stainless steel 304, stainless steel 316 or hardened steel, special materials please inquire |

| Motor 7.5 kW: 8-pole (IE3 motor) 11.0 / 15.0 / 18.5 / 22.0 kW: 4-pole (IE3 motor) 400V, 50Hz, special models please inquire 3 thermistors (overheat protection) Explosion-proof motor Ex II 3G Ex nA IIC T3 Gc Special design 13.5 kW: Ex II 2G Ex eb IIC T3 Gb Optional: rain cover (stainless steel 304) | Adjustment range Vertical direction via upper arm (±11°), optional ± 30° via hydraulic cylinder or gear Rack and pinion adjustment Tank opening: 700 x 700 mm (seal plate 98 cm) 800 x 800 mm (seal plate 120 cm) 1000 x 1000 mm (seal plate 143 cm) |

| Gear Spur gear drive, helical gear, low noise, reduction ratio i = 3.69 or 5.31 Self-circulating gear oil Oil change required every 2,000 operating hours | Explosion-proof Zone 2 (outside tank), Explosion-proof Zone 1 (inside tank) Special design FR4 13.5 kW suitable for explosion-proof Zone 1 (outside tank) Mechanical component classification: C∈ Ex II 2G Ex h IIA T3 Gb |

| Control (optional) Star-delta starter Soft start or frequency converter Delivery does not include cables |

| Tank dimensions | Model | Speed (r/min) | Power (kW) | Impeller diameter (mm) | Axial force (kN) | Flow rate (m/s) |

| Φ10*13 | TOP3007/1 | 200 | 7.5 | 850 | 2.0 | 2.6 |

| Φ14*14 | TOP3007/2 | 275 | 11 | 800 | 2.9 | 3.2 |

| Φ16*16 | TOP3007/3 | 400 | 11 | 620 | 2.5 | 3.9 |

| Φ19*17 | TOP3007/4 | 275 | 15 | 850 | 4.1 | 3.6 |

| Φ19*19 | TOP3007/5 | 400 | 15 | 660 | 3.3 | 4.3 |

| Φ20*20 | TOP3007/6 | 275 | 18.5 | 880 | 4.4 | 3.7 |

| Φ22*22 | TOP3007/7 | 400 | 18.5 | 700 | 3.9 | 4.3 |

| Φ24*24 | TOP3007/8 | 400 | 22 | 750 | 4.5 | 4.5 |

Next

Message

Please provide the following valid information, and we will contact you as soon as possible.

Related Products

A technology-based enterprise focusing on mechanical stirring equipment and industrial intelligent control systems. Products are mainly used in the fields of pharmaceutical chemicals, biomass energy, energy storage batteries, fine chemicals, and environmental protection.

TOP3006 long-shaft fixed side-entry mixer

A technology-based enterprise focusing on mechanical stirring equipment and industrial intelligent control systems. Products are mainly used in the fields of pharmaceutical chemicals, biomass energy, energy storage batteries, fine chemicals, and environmental protection.

TOPH2013 series GXJ industrial double planetary mixer

A technology-based enterprise focusing on mechanical stirring equipment and industrial intelligent control systems. Products are mainly used in the fields of pharmaceutical chemicals, biomass energy, energy storage batteries, fine chemicals, and environmental protection.

TOPH2014 series LGXJ industrial double planetary mixer

A technology-based enterprise focusing on mechanical stirring equipment and industrial intelligent control systems. Products are mainly used in the fields of pharmaceutical chemicals, biomass energy, energy storage batteries, fine chemicals, and environmental protection.