BLOG

We look forward to meeting you at the event, let's talk about your current needs.

Introduction to magnetic stirrers

Release time:

2025-07-21

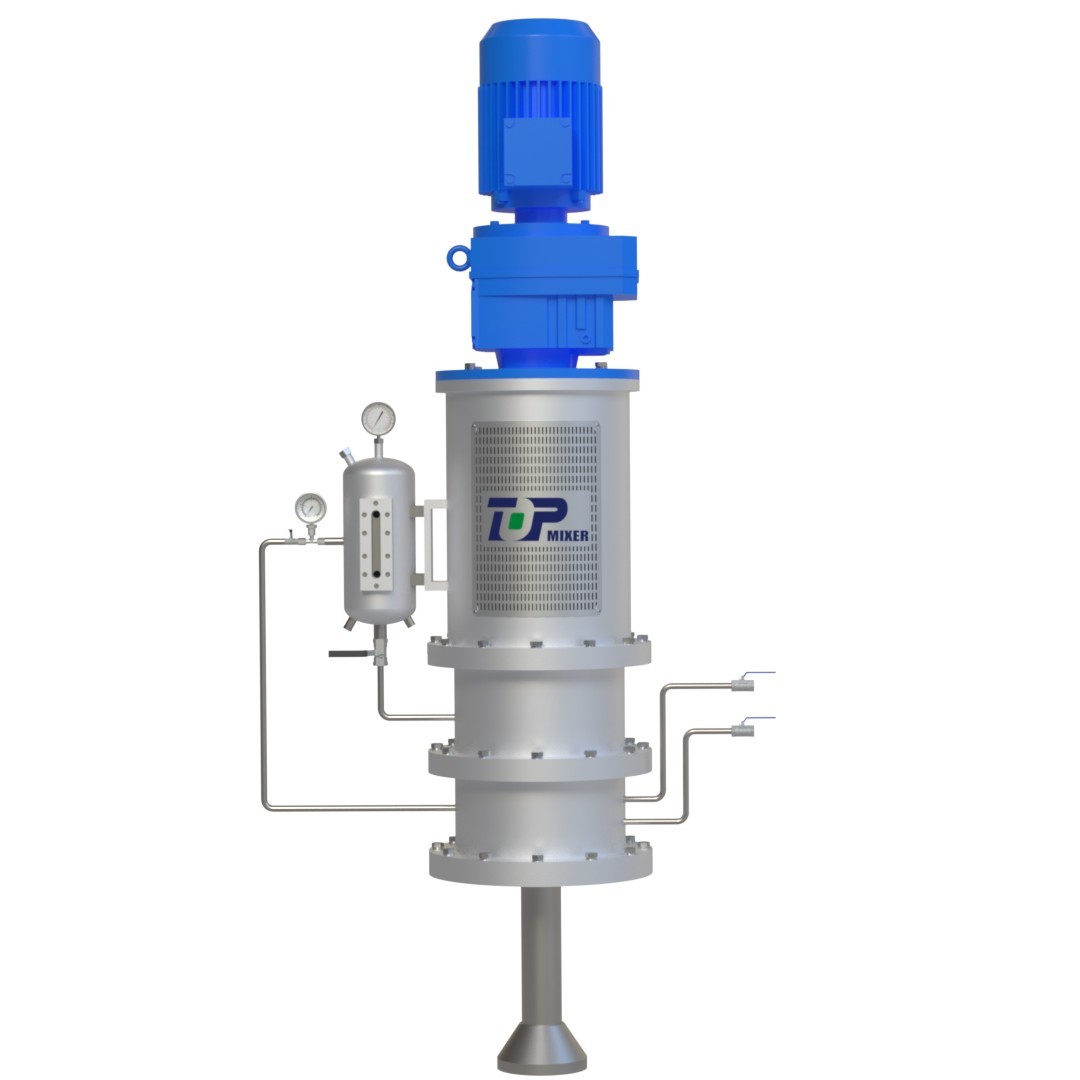

A magnetic top-entry stirrer is a stirring device that mounts a magnetic stirrer on top of a container. It is widely used in laboratories and industrial production. The following is an introduction to magnetic top-entry stirrers, including their working principle, technical characteristics, and application scenarios.

Introduction to Magnetic Stirrers

A magnetic top-entry stirrer is a stirring device with a magnetic stirring mechanism installed on top of the container. It is widely used in laboratories and industrial production. The following is an introduction to magnetic top-entry stirrers, including their working principle, technical characteristics, and application scenarios.

1. Working Principle

The working principle of a magnetic top-entry stirrer is based on magnetic coupling. Its core components include:

External magnetic rotor: Driven by a motor to rotate, generating a rotating magnetic field.

Internal magnetic rotor (stir bar): Placed in the liquid in the container, it rotates under the action of the magnetic field of the external magnetic rotor.

Isolation sleeve: Separates the external and internal magnetic rotors, preventing liquid leakage and protecting the motor and magnetic system.

When the motor drives the external magnetic rotor to rotate, the rotating magnetic field generated by the external magnetic rotor penetrates the isolation sleeve and acts on the internal magnetic rotor, causing it to rotate synchronously. The rotation of the internal magnetic rotor drives the liquid to form an eddy current, thereby achieving uniform stirring of the liquid.

2. Technical Characteristics

Contactless drive: Contactless drive is achieved through magnetic coupling, avoiding the shaft seal leakage problem of traditional mechanical stirrers, especially suitable for handling corrosive or high-purity liquids.

Good sealing performance: Because the inner and outer magnetic rotors are completely isolated by the isolation sleeve, the liquid will not leak during stirring, and the safety is high.

Easy installation: The stirring device is installed on top of the container, making installation and removal convenient and maintenance simple.

Wide range of applications: It can handle liquids of different viscosities, and different shapes and sizes of stir bars can be selected as needed.

Low shear force: Suitable for samples sensitive to shear force, such as cell culture and suspensions.

Energy-efficient and efficient: Magnetic coupling transmission has high efficiency and low energy consumption.

3. Application Scenarios

Laboratory: Used for solution mixing, dissolution, chemical reactions, and other experimental operations, especially suitable for experiments with high requirements for sterility and non-contamination.

Industrial production: In the chemical, pharmaceutical, and food industries, it is used to stir high-viscosity liquids and mix materials in reactors.

Biopharmaceuticals: In bioreactors, it is used in cell culture and biofermentation processes to ensure sterile operation.

4. Advantages and Challenges

Advantages:

No leakage risk: Magnetic coupling avoids the leakage problem of mechanical seals, improving safety.

Easy operation: Convenient installation and use, low maintenance cost.

Strong applicability: Suitable for various liquids and process conditions.

Challenges:

Difficulty in scaling up: For large containers, the manufacturing and installation of magnetic stirrers are more difficult, and the strength and stability of the stirring shaft are required to be high. The stirring effect of high-viscosity liquids is limited: When handling extremely high-viscosity liquids, the stirring efficiency may be lower than that of mechanical stirrers.

With its unique contactless drive method and efficient and safe stirring performance, the magnetic top-entry stirrer has become an indispensable device in modern laboratories and industrial production.

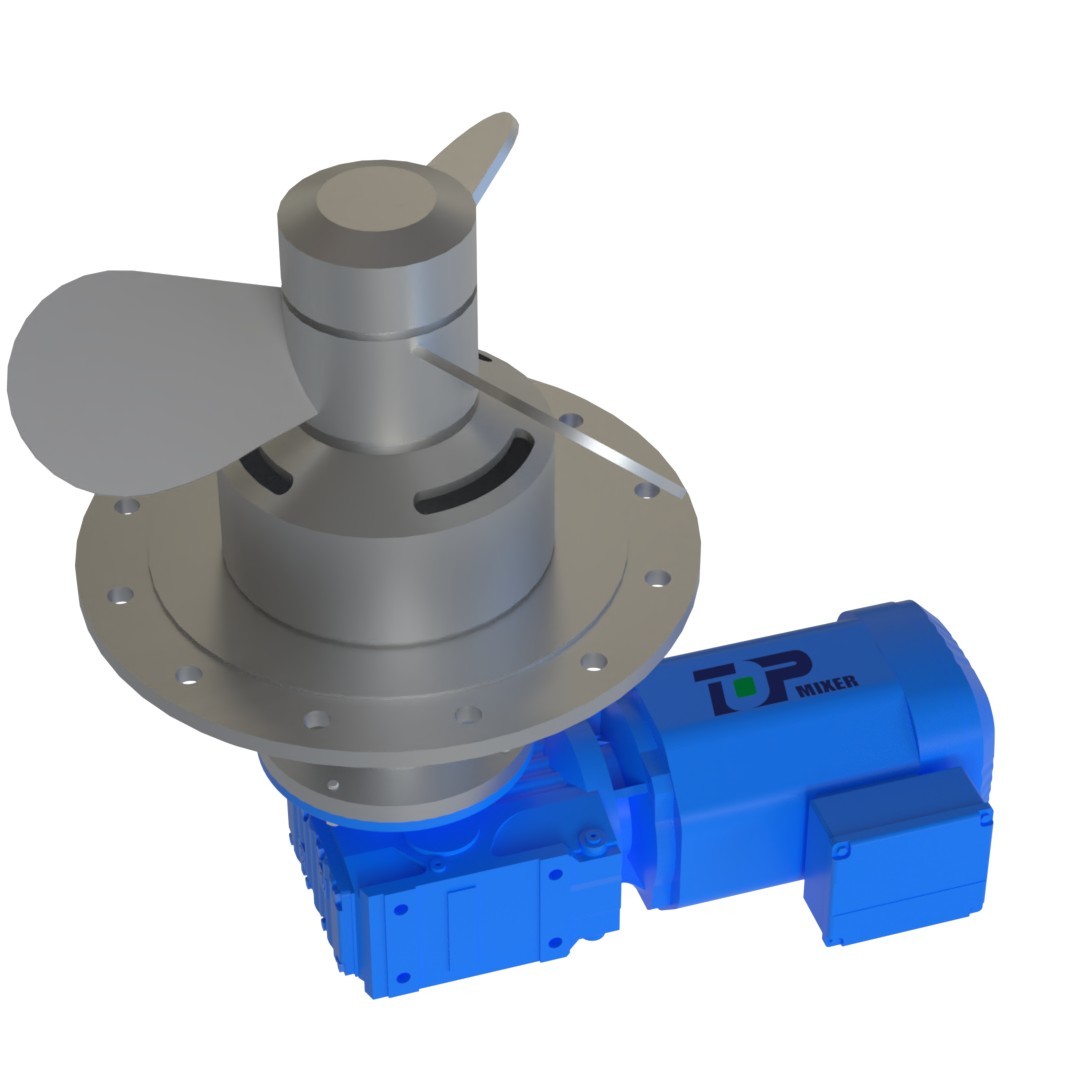

Introduction to Magnetic Bottom-Entry Stirring

A magnetic bottom-entry stirrer is a stirring device that uses magnetic drive technology. Its stirring device is located at the bottom of the container, and the stirring paddle rotates through contactless magnetic coupling transmission, achieving uniform mixing of the liquid. The following is a detailed introduction to magnetic bottom-entry stirrers:

1. Working Principle

Magnetic bottom-entry stirrers utilize the principle of attraction and repulsion of magnetic materials. An external magnetic drive device generates a rotating magnetic field, driving the internal stirring paddle (or stir bar) to rotate. The working process is as follows:

The external magnetic drive device (such as a motor-driven magnet) generates a rotating magnetic field.

The internal stirring paddle (or stir bar) rotates synchronously with the external magnetic field through magnetic coupling.

The rotation of the stirring paddle drives the liquid in the container to form an eddy current, thereby achieving uniform mixing of the liquid.

2. Technical Characteristics

No leakage risk: Using magnetic coupling transmission, no mechanical seal is required, avoiding the leakage problem of traditional mechanical seals, especially suitable for handling toxic, harmful, flammable, explosive, or high-purity materials.

High cleanliness: The stirring device is located at the bottom of the container, reducing stirring dead corners and ensuring uniform mixing of materials, suitable for applications with high cleanliness requirements.

Long lifespan design: Using high-performance magnets and corrosion-resistant materials, such as 316L stainless steel, extends the service life of the equipment.

Safe and reliable: Static sealing with a welded isolation sleeve replaces dynamic mechanical seals, solving the problems of leakage associated with traditional seals.

Efficient mixing: The stirring paddle installed at the bottom can generate good circulation flow, improving mixing efficiency.

3. Application Scenarios

Magnetic bottom-entry stirrers are widely used in the following fields:

Pharmaceutical industry: Used in the mixing and reaction processes of drug production to meet GMP standards.

Biotechnology: In biofermentation and cell culture processes, ensuring sterile operation.

Food and beverage industry: Used in food processing for stirring and mixing to ensure product quality and safety.

Chemical industry: Used in the mixing and reaction of fine chemicals.

4. Advantages and Challenges

Advantages:

No leakage risk, high safety.

High cleanliness, suitable for industries with high hygiene requirements.

Long lifespan design, reducing maintenance costs.

Challenges:

For high-viscosity materials, the mixing efficiency may be lower than that of mechanical mixers.

Relatively high equipment cost.

Magnetic bottom-entry mixers play a significant role in the pharmaceutical, biotechnology, food, and chemical industries due to their unique leak-proof, high-cleanliness, and long-life characteristics. They are an indispensable part of modern industrial production.

Previous

Previous