Hello, welcome to the official website!

Contact Number:400-000-0000

- All

- Product Management

- News

- Introduction

- Corporate Branches

- FAQ

- Corporate Video

- Corporate Brochure

BLOG

We look forward to meeting you at the event, let's talk about your current needs.

Introduction to high shear emulsifiers

Release time:

2025-07-21

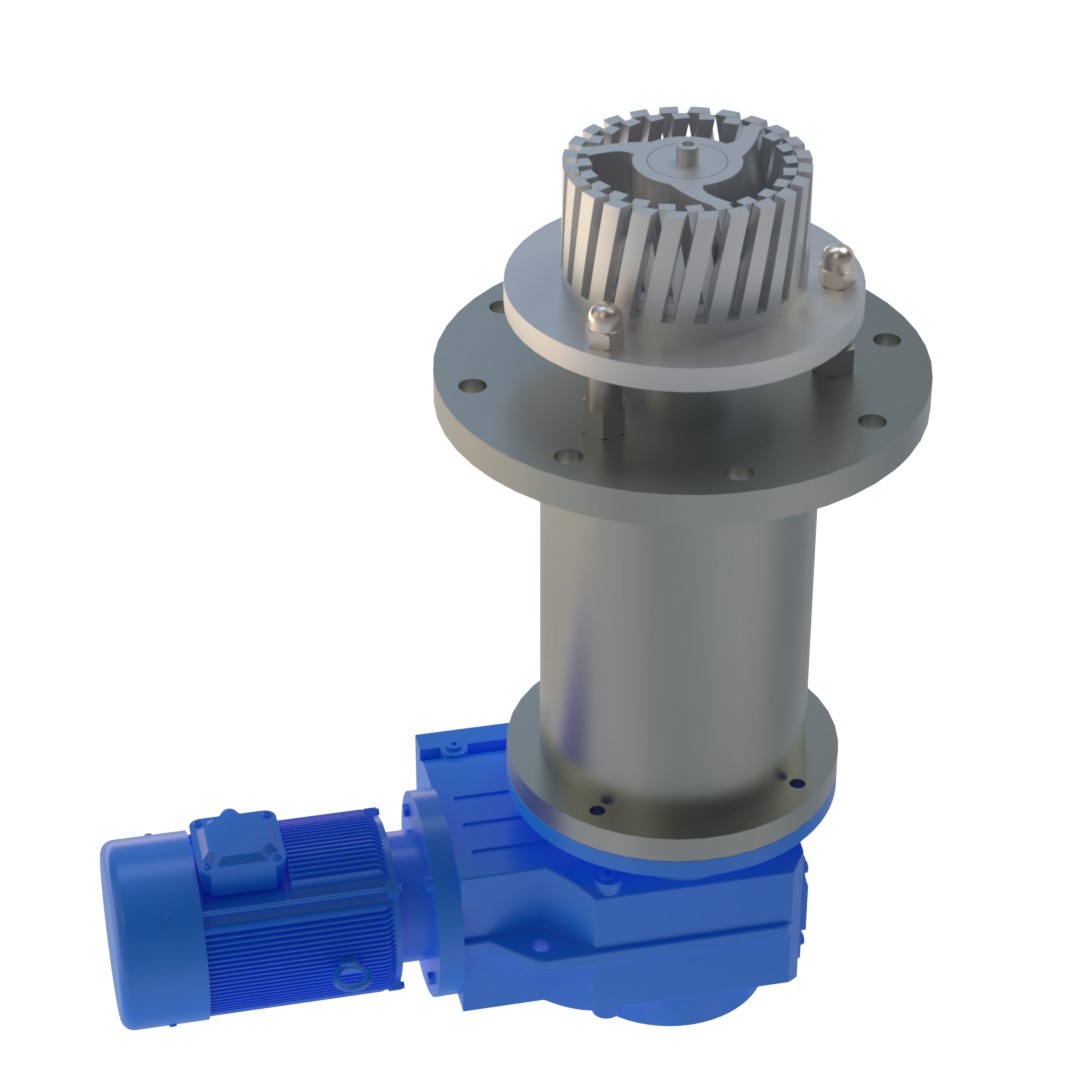

A high-shear emulsifier is an industrial device that uses mechanically generated high shear forces to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gas phases. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and evenly distributing materials to form stable emulsions or suspensions.

A high-shear emulsifier is an industrial device that uses mechanically generated high shear forces to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gaseous materials. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and evenly distributing materials to form stable emulsions or suspensions.

1. Working Principle

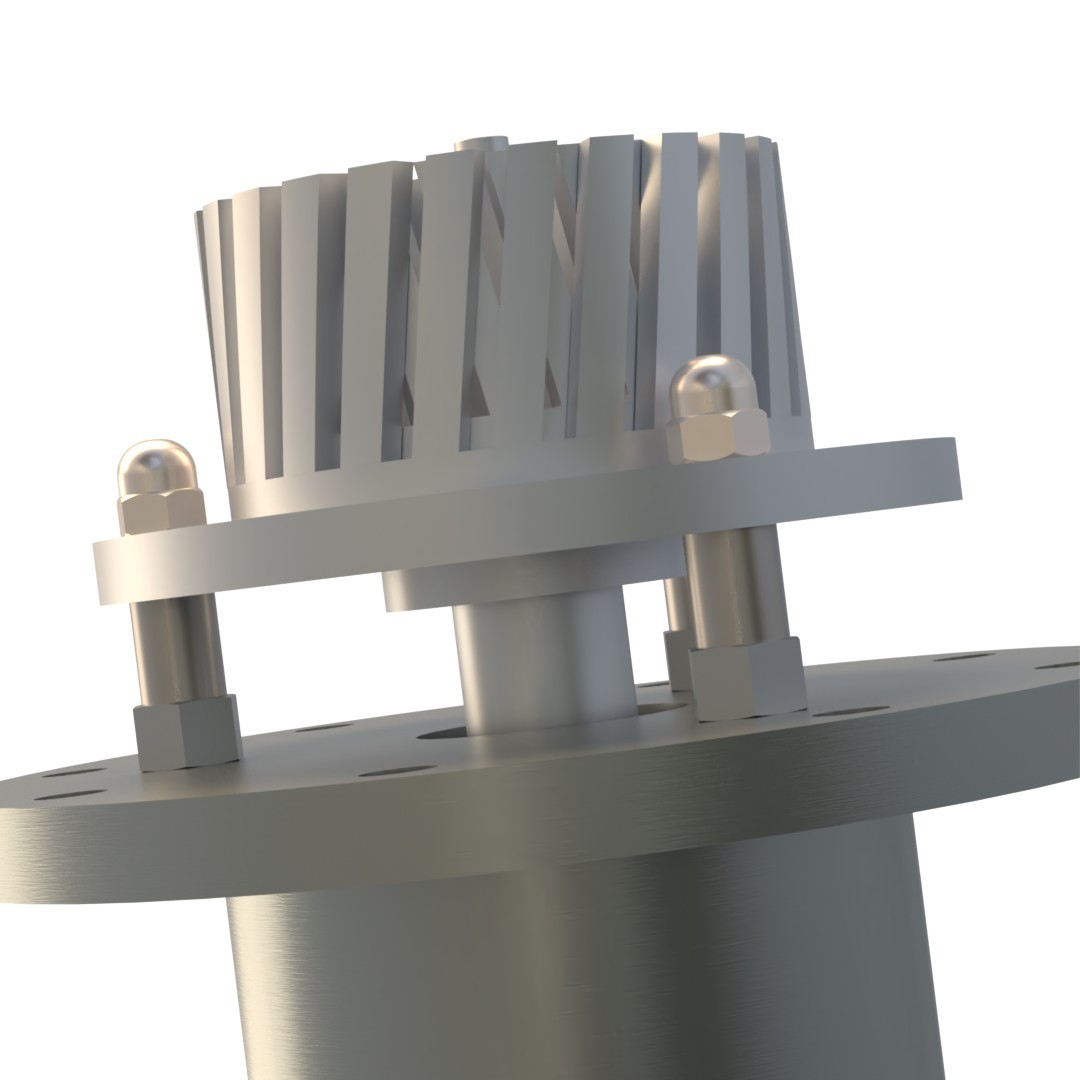

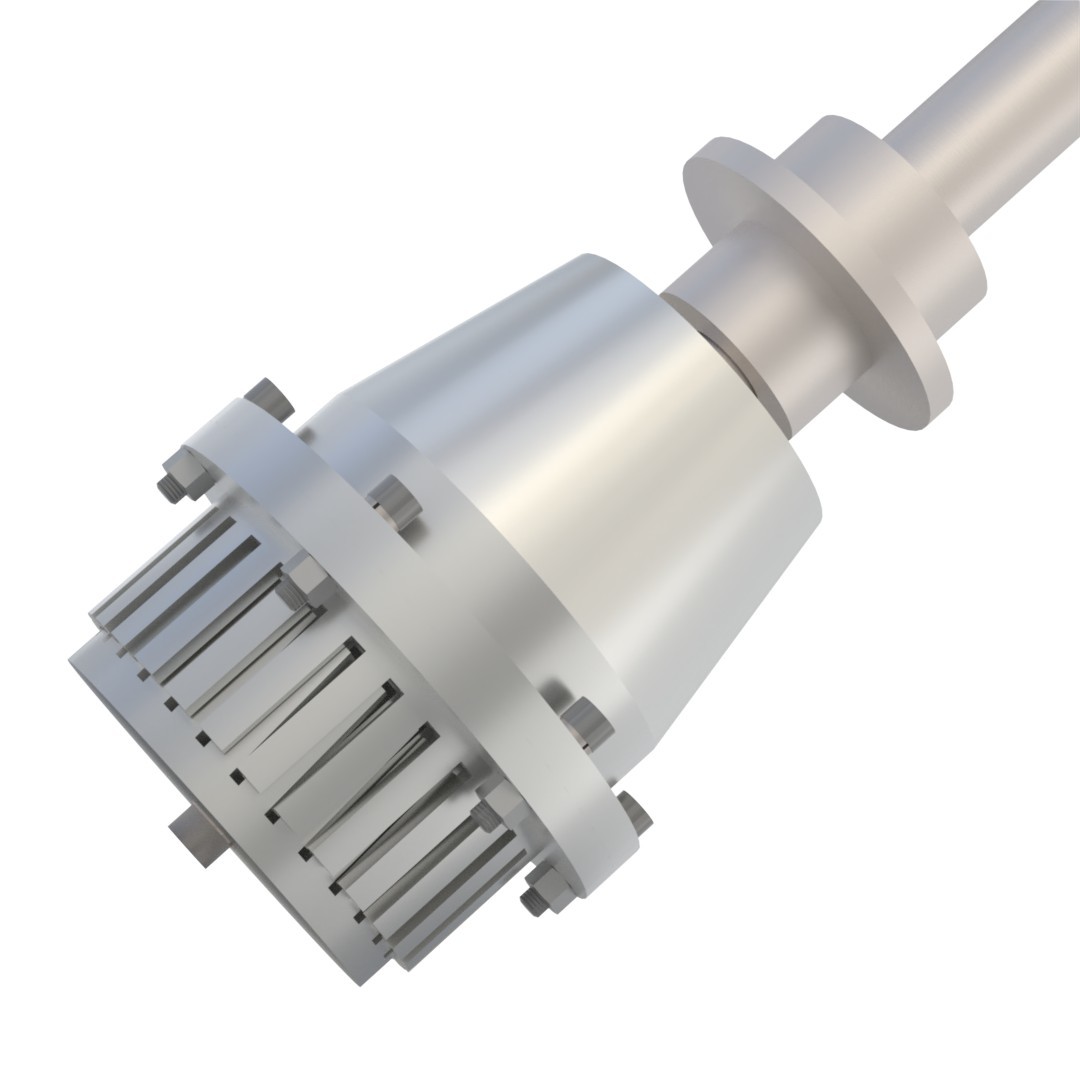

The core components of a high-shear emulsifier are the rotor and stator. Its operation is as follows:

Suction: The high-speed rotating rotor generates strong centrifugal force, drawing materials from the inlet area of the working head into the working chamber.

Primary Emulsification: Under centrifugal force, materials are flung into the narrow gap between the stator and rotor, undergoing centrifugal compression and shearing forces, achieving initial dispersion and emulsification.

Injection: The linear velocity at the outer end of the rotor is very high (reaching 15m/s or more, up to 40m/s), and the materials are further refined under strong shear forces and ejected from the stator slots.

Circulatory Emulsification: The ejected material changes flow direction due to resistance from the container wall, forming strong upward and downward turbulent flows. After multiple cycles, the material is finally dispersed, emulsified, and homogenized.

2. Technical Features

High-efficiency shearing: Through the high-speed relative movement of the rotor and stator, strong shear forces are generated, rapidly reducing droplet size and achieving efficient emulsification and dispersion.

Multiple material processing: Suitable for mixing and emulsification of various materials, including liquid-liquid, liquid-solid, and gas-liquid, with good handling of high-viscosity and high-concentration materials.

Compact structure: The equipment has a compact structure, easy installation, and is easy to operate and maintain.

Multiple configurations: Offers models with different power, speeds, and installation methods to meet different production scales and process requirements.

Material selection: Components in contact with materials usually use corrosion-resistant materials such as 304 or 316L stainless steel to ensure equipment durability and material hygiene and safety.

3. Application Areas

Food industry: Used in the production of dairy products, beverages, seasonings, etc., improving product stability and taste.

Chemical industry: Used in the production of coatings, adhesives, fine chemicals, etc., achieving uniform mixing and dispersion of materials.

Pharmaceutical industry: Used in the preparation of ointments, emulsions, suspensions, etc., ensuring uniform distribution of drug components.

Cosmetics industry: Used in the production of lotions, creams, serums, etc., improving product stability and efficacy.

With its high efficiency, flexibility, and reliability, the high-shear emulsifier has become an indispensable piece of equipment in modern industrial production, significantly improving production efficiency and product quality.

Previous

Address: No. 9, Xinyuan Road, Qianzhou Industrial Park, Wuxi City

Tel: +86-510-83383966

Tel: +86-13706183972 Manager Xu

Tel: +86-514-84380409

Email: topchina2003@top-mixer.com

Email: Rose.xu@top-mixer.com

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.